TECHNOLOGY & AUTOMATION

Optimising time to improve performance

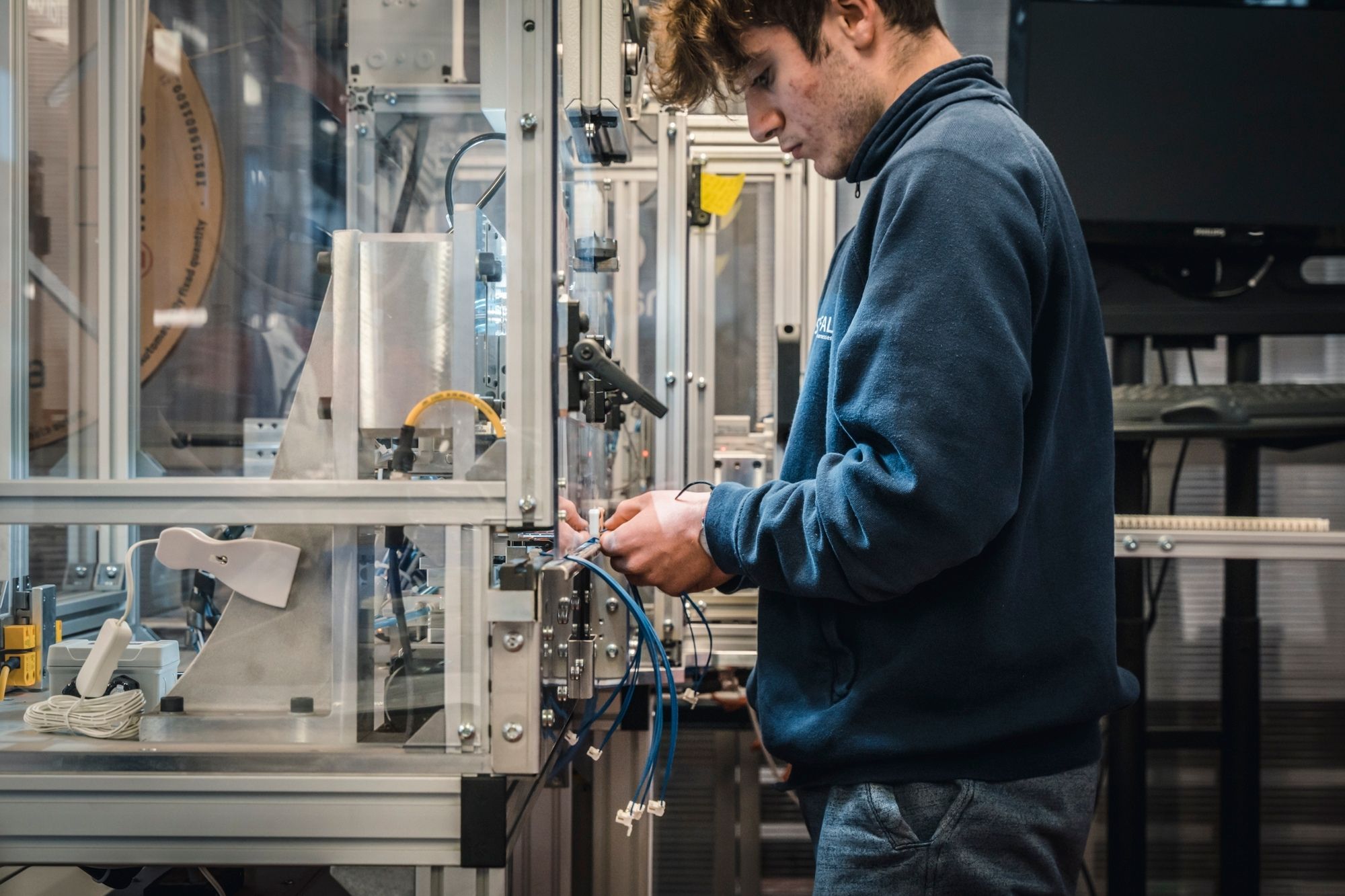

Stefal’s name is a guarantee: we take the utmost care in planning projects, investing in state-of-the-art technology, meeting customer requirements and monitoring the production cycle.

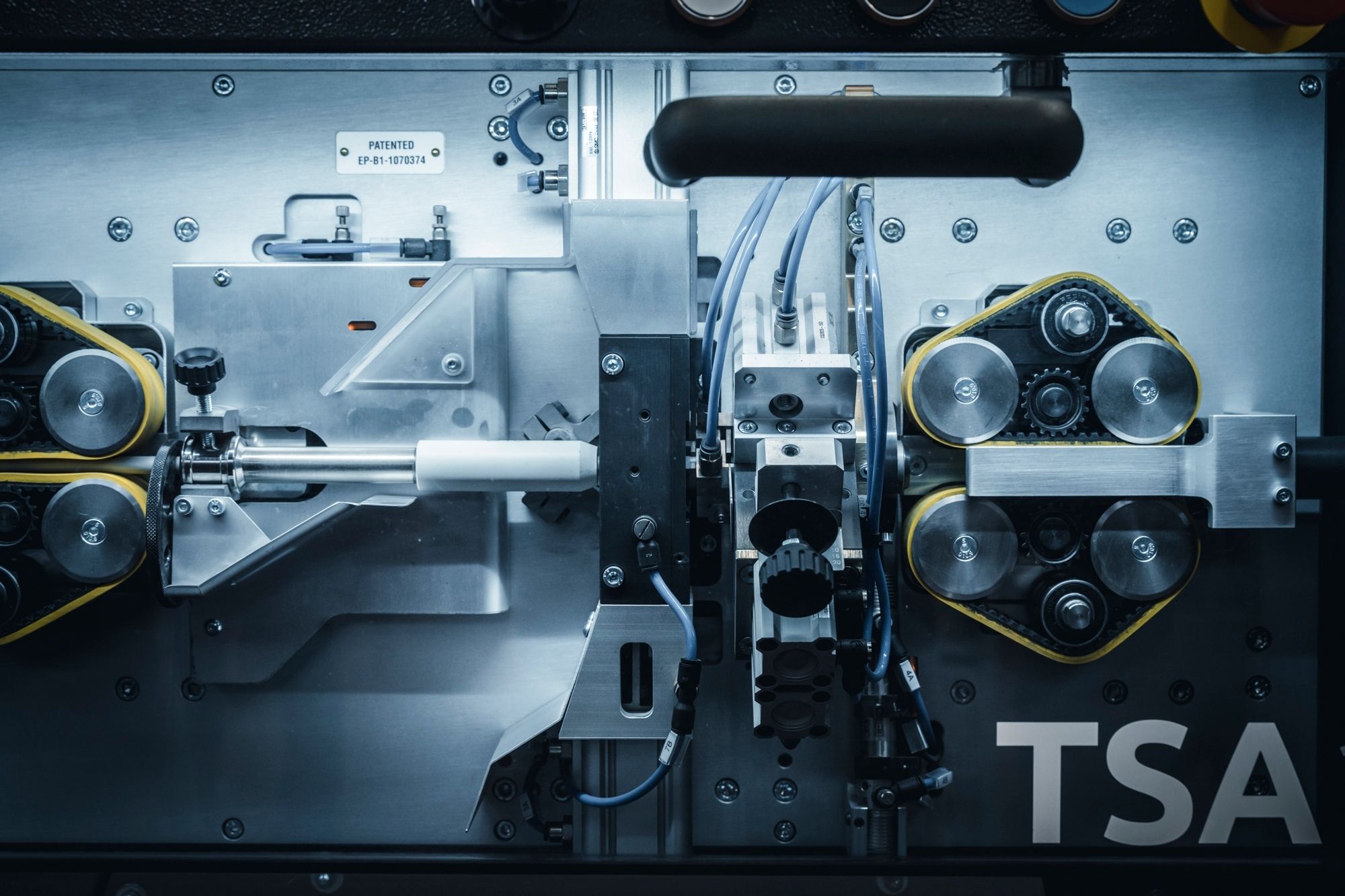

The company’s automation inventory includes 20 automatic cutting-stripping-crimping machines and 7 automated lines for cutting multipolar cables of all types. The company’s unrivalled competitiveness in the technological field allows it to work on small to medium-sized products, a service that few companies nationwide can afford to offer.

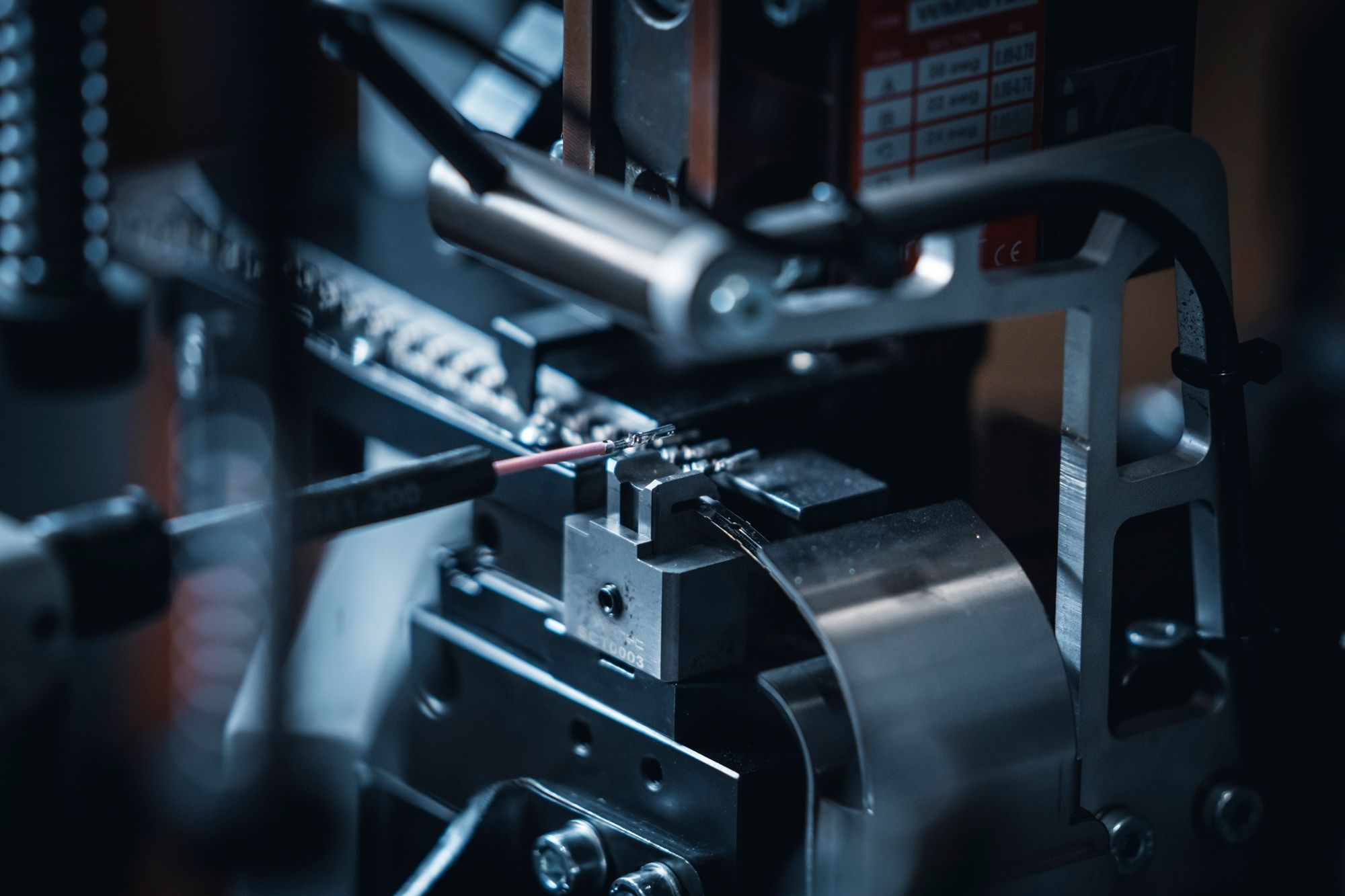

While one part of the machinery is dedicated to working on medium-sized cables, another, characterised by high precision, is dedicated to the production of smaller, more specific items. This makes it easier for us to work with manufacturers who expect certain customisations for a particular type of production: software checks on performance and output, integrated with a production check-up via automatic systems, allows our operators to provide useful information for the customer in real time.

Constant maintenance of all equipment guarantees continuity and high-level performance.

Already equipped with state-of-the-art machinery, the department expects to double its potential within a few years, with the aim of automating any process.

For these projects, our company has realised that it will need to work in new premises: looking to the future, the company will invest its resources in the construction of a new building.

Our flagship machines

Automatic cutting – stripping – crimping machines

Lines with automatic multipolar cable cutting machines

Manual benchtop crimping machines

Automatic benchtop cutting – stripping – crimping machines

Semi-automatic machine for machining RAST connectors